The A380 joins the A319neo and A350 as the first three Airbus aircraft to fly using 100% Sustainable Aviation Fuel20 (SAF)

Blagnac airport (Toulouse-France) has witnessed a new milestone in aviation as the iconic Airbus A380 took off on 100% Sustainable Aviation Fuel (SAF). During the three-hour flight, the A380’s 4 turbines (equipped with Rolls-Royce Trent 900 engines), were powered by 100% Sustainable Aviation Fuel (SAF) provided by Total Energies which, unlike other solutions to reduce their carbon footprint, is not mixed with any other type of traditional fossil fuel. This flight is not the first of its kind for Airbus, but it is a milestone because it was made with the A380, the world’s largest passenger aircraft. Furthermore, this marks the first test campaign using 100% Sustainable Aviation Fuel (SAF) in all phases of the test: take-off, climb, cruise, descent and landing. This type of sustainable fuel is produced in Normandy at the Le Havre (France) facility and has been developed with a base of esters and hydro-processed fatty acids, mainly obtained from recycled cooking oil and other waste fats. A solution that can provide a reduction in greenhouse gas emissions of between 53% and 71% of total lifecycle emissions, according to the company’s own sources, compared to the current use of conventional aviation fuels. This is a milestone for the reduction of aviation’s carbon footprint.

Three aircraft flying on 100% Sustainable Aviation Fuel (SAF) in just 12 months Following this test, the A380 joins the A319neo (October 2021) and A350 (March 2021) as the third Airbus aircraft to be able to fly on 100% Sustainable Aviation Fuel (SAF) in less than a year. The next steps, as Airbus itself reports in the note published on its website, are to achieve certification for its aircraft to be able to fly with this type of fuel by 2030. At present, all Airbus aircraft are certified to fly on a mixture of SAF and kerosene. These milestones, which will surely continue to be repeated on a more regular basis in this decade, aim to underpin firm steps towards the aviation industry’s goal of zero emissions by 2050. Thus, Airbus announced that by 2035 the market will have the first zero-emission aircraft model.

Why does a plane fly?

The aeronautical sector is one of the most demanding and rigorous human activities when it comes to manufacturing the parts that make up an aircraft, but how complex is the reason why such a heavy machine is capable of taking flight? It is indeed highly complex, but, just like everything in this life, it has a rational, simple explanation.

Imagine we take a balloon full of air and untie the knot. What is the result? The air trapped inside the balloon seeks to exit abruptly through the open end of the balloon, causing it to fly off in any direction. Yes, dear reader, this is just how an aeroplane’s jet engine works, namely by means of a current of air that comes out through the rear of the engine.

By now, you will have realised that it is a little more complex than that, and that we have to dig a little deeper if we really want to know why a plane flies. Here we go.

The main blocks of a jet engine

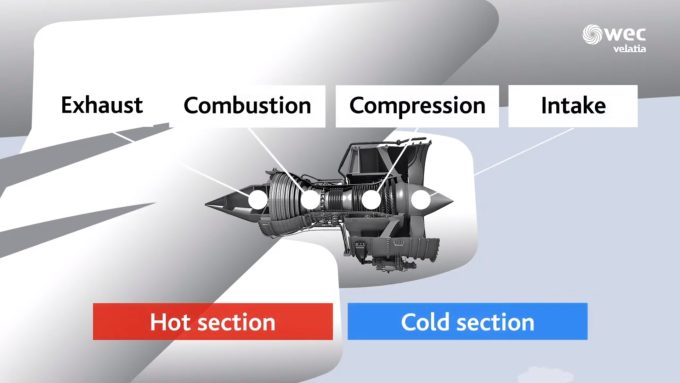

A conventional jet engine is divided into four large blocks: intake, compression, power, and exhaust.

A large propeller at the front (intake) absorbs the air and drives it to the inside and around the outside of the engine, surrounding the core of the turbine. It is through this core (located, logically, right in the centre of the engine) that the air advances towards the compressor.

Remember our beloved balloon? The air that reaches the compression zone is severely pressed, just like when pressing a balloon, and delivered to the combustion chamber, where it mixes with the engine fuel. Imagine a great current of hot air expanding massively inside a sealtight chamber, creating a high-speed jet that is launched towards the back of the aeroplane’s engine, causing it to take off in a forward movement.

The greater the speed, the greater the engine’s thrust. At this moment, when the temperature of our jet engine reaches (just!) 1500 degrees Celsius, the parts demonstrate their quality in meeting the demands they are subjected to. Nothing can go wrong.

The jet of hot air also turns the plane’s turbine, connected to the front of the engine by a shaft. It works in the same way as a windmill. Think of each blade of this high-pressure turbine pushing with a force similar to that of a Formula 1 race car.

Excess hot air is released at high speed from the back of the engine (exhaust), generating the energy needed for the plane to reach its destination on time. That’s how a plane flies.

If, after all this, you still have not figured out how a jet engine works, don’t worry. This video is sure to clear up any questions: